How to use three-phase asynchronous motor correctly? These seven points are very

Reasonable selection and correct use of three-phase asynchronous motor are two important links to ensure its normal operation. However, after many people bought it, the normal operation of the motor will no longer be controlled, which is wrong. Today's editor will show you how to use and maintain the motor correctly.

(1) power supply conditions. The supply voltage, frequency and number of phases shall be equal to the motor nameplate data. The power supply voltage is symmetrical system, and the deviation of voltage rating shall not exceed ± 5% (when the frequency is rated); the deviation of frequency shall not exceed ± 1% (when the voltage is rated).

(2) environmental conditions. The ambient temperature of the motor operation site shall not exceed 4O ℃, which is suitable for indoor ventilation, drying, etc.

(3) load conditions. The performance of the motor shall be suitable for starting, braking, load with different rating and load conditions such as speed change or speed regulation. The load shall not exceed the rated power of the motor.

The following points shall be paid attention to in the maintenance of normal operation:

(1) the temperature of the motor in normal operation shall not exceed the allowable limit. Runtime. The personnel on duty shall often pay attention to monitoring the temperature rise of each part.

(2) monitor the motor load current. Motor overload or failure. The stator current will increase sharply. Overheat the motor. The electrical equipment shall be equipped with ammeter to monitor the motor load current. The load current of the motor in normal operation shall not exceed the rated current value specified on the nameplate.

(3) monitor the power supply voltage, frequency change and voltage imbalance. The supply voltage and frequency are too high or too low. The unbalance of three-phase voltage will cause current unbalance. May cause motor overheating or other abnormal phenomena. The current imbalance shall not exceed 10%.

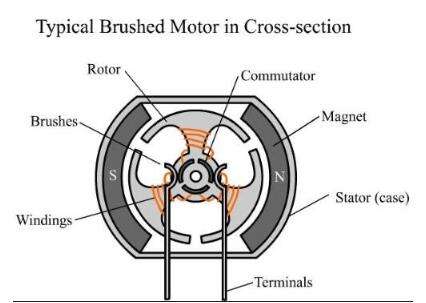

(4) pay attention to the smell, vibration and noise of the motor. If the temperature of the winding is too high, the insulation will be burnt. There are some problems. Especially the mechanical array. It will soon be reflected as vibration and noise, so when you smell burning smell or find abnormal vibration or rubbing sound or extra loud buzz or other noise. The power shall be cut off immediately.

(5) check the bearing heating and oil leakage frequently. Change lubricating oil regularly. The lubricating grease of rolling bearing shall not exceed 70% of the volume of bearing chamber.

(6) pair wound rotor motor. The contact between brush and collecting ring, brush wear and spark shall be checked. If the spark is serious, it is necessary to clean the collector ring surface in time and correct the electric shock pressure.

(7) pay attention to keep the inside of the motor clean and do not allow water drops, oil stains and sundries to fall into the motor. Here we remind you that the air inlet of the motor must be unobstructed.